Mot Bay Process

Product Support

Planning an upgrade or a brand new MOT bay and choosing the appropriate equipment can be a daunting task. As a founding member of the GEA, we have a deep understanding of modern MOT requirements and how to make the best use of available space.

Continental will provide you with your own project manager, who will assist you every step of the way to ensure maximum efficiency and on time completion.

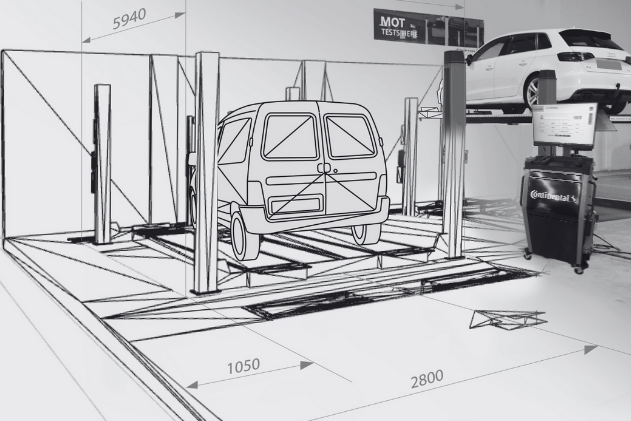

Your product manager will take detailed measurements onsite. They will then recommend which equipment will fit in terms of Class 4 or Class 7, floor and height space and personal preference.

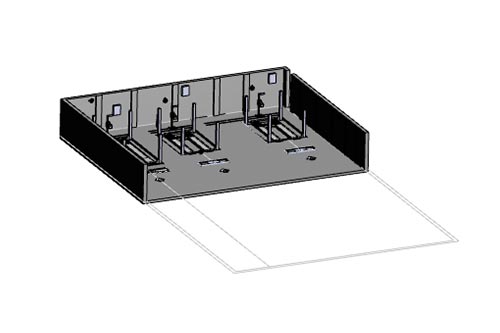

Our professional in-house designers will produce detailed CAD drawings of your workshop proposal to give you the best outlook of what your equipment would look like in your workshop.

Your project manager will assist you through the application process. Our CAD drawings are also produced to meet DVSA specifications to support your application and obtain an Agreement in Principle (AIP).

All sizes are marked out on the floor before the first cut begins to make sure all DVSA size requirements are correct. The brake tester needs to be at least 600mm away from a recessed lift to allow a level surface when carrying out a brake test.

Digging commences to house a recessed lift and brake tester.

Concrete is poured in the lift and brake tester recess to ensure a certain depth and adequate strength. Civil works takes 10-14 days to complete to ensure concrete is properly set.

After delivery, our GEA accredited and qualified engineers will install your equipment.

Once your equipment has been installed, we will show you how to use your new Continental equipment onsite. All examiners must apply for a VT01 through DVSA prior to this.

DVSA will then complete the final checks to ensure your bay meets DVSA requirements.

Once you’re up and running, we’ll continue to provide you with ongoing customer support. We offer a variety of maintenance and calibration contracts to keep your equipment in the best working condition and maximise its operational life.